How to Perform Harness Inspections: A Guide to Staying Safe and Compliant

Let’s chat about something that might not be the most thrilling part of your day but is absolutely crucial: inspecting your fall protection harness. Think of it as giving your gear a health check-up to ensure it’s in tip-top shape when you need it most.

Why Bother with Inspections?

Imagine your harness as your best mate on the job, always having your back—literally. Regular inspections ensure that this mate is reliable and ready to catch you if things go south. Plus, staying on top of inspections keeps you in line with the Safety, Health and Welfare at Work (General Application) Regulations 2007.

When Should You Inspect?

- Before and After Each Use: Give your harness a once-over every time you gear up and after you’re done.

- Every 6 Months: A thorough examination by a competent person is a must at least twice a year. If you’re working in harsh conditions or the manufacturer suggests it, consider more frequent checks.

What to Look For?

- Tags and Labels: Ensure the manufacturer’s tag is present and legible. It should display:

- Manufacturer’s name

- Serial number

- Model number

- Size

- Date of manufacture

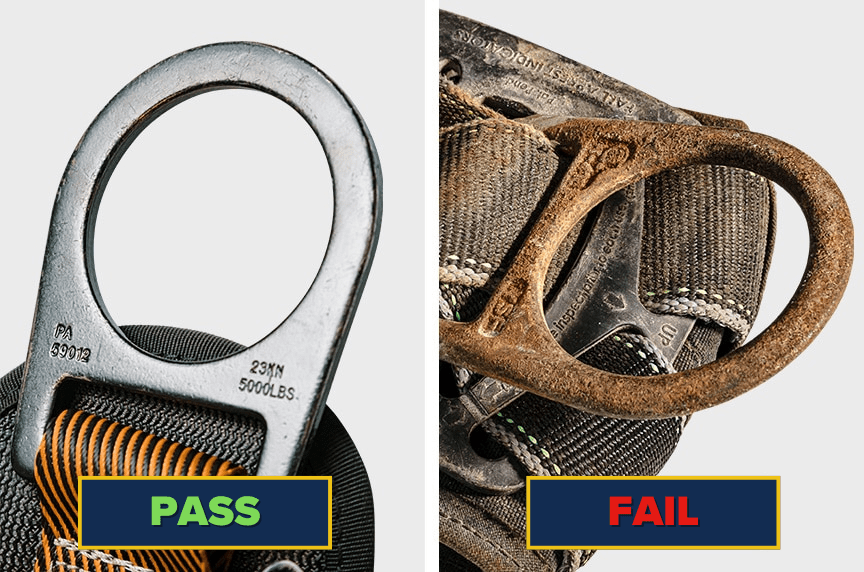

- Hardware: Check all metal parts like D-rings and buckles for:

- Deformities

- Cracks

- Corrosion

- Missing or damaged components

- Webbing and Stitching: Examine the fabric parts for:

- Cuts, tears, or holes

- Frayed or loose stitching

- Burns or signs of heat damage

- Chemical stains or damage

- Excessive wear or deterioration

Who Should Inspect?

- You: Yes, you! Before and after each use, give your harness a quick visual and tactile inspection.

- Competent Person: Someone with the know-how should perform a detailed inspection every six months.

What If You Find a Fault?

If you spot any issues, retire the harness immediately. Don’t take risks with faulty equipment. Replace it or have it inspected by a professional before using it again.

What Are the Most Common Reasons for a Harness to Be Rejected?

The most common reasons a harness will be disqualified from service are:

- Illegible tag

- Heat damage

- UV damage

- People writing on their harness with a marker on the load-bearing webbing

What it comes down to is one will never really be able to prove what marker was used to make a mark on the harness webbing. Therefore, one can only go in the direction of some chemical was introduced, and some level of damage is possible.

Need Professional Inspection Services?

At Hoistech, we offer comprehensive harness inspection services to keep you safe and compliant. Our experts will:

- Conduct detailed examinations of your fall protection equipment.

- Provide reports as required under the Safety, Health and Welfare at Work (General Application) Regulations 2007.

- Identify any equipment that is unfit for use and explain why.

Stay safe out there, and remember: a well-inspected harness is a lifesaver!

Looking for fall protection and height safety equipment? Look no further… Just click below and get equipment you can trust!