Reglift – Ergonomic Lifting Solutions

Cleanroom-Ready | Ergonomic | Compliant

Reglift lifting trolleys are engineered for the most demanding environments—where safety, hygiene, and precision matter most. Manufactured from high-grade stainless steel, Reglift systems are ideal for industries requiring frequent washdowns, sterile conditions, or precision handling. With manual and electric models available, Reglift combines ergonomic design with rugged durability—helping you improve operator safety, protect your products, and stay compliant with regulatory standards.

✔ Cleanroom-compatible

✔ Chemical and detergent resistant

✔ Customisable tools and attachments

✔ CE marked and EU compliant

✔ Manufactured in Europe

Pharmaceutical

Food & Beverage

Logistics & Warehousing

Pharmaceutical & Biotech Manufacturing

Reglift for Pharma

In GMP-regulated environments, lifting gear must be as clean and compliant as your production lines. Reglift’s stainless steel construction eliminates contamination risks from paint flaking or surface corrosion. Its smooth, easy-clean design supports cleanroom protocols and hygiene compliance under HPRA, EMA, and HSA standards.

Key Features:

– Designed for Class A–D cleanroom zones

– Compatible with stainless steel drums, totes, and isolators

– Zero contamination risk—no painted surfaces

– Full GA1-certification service available through Hoistech

Popular Use Cases:

– Transferring materials in sterile compounding labs

– Lifting drums in GMP production suites

– Handling filters, vials, and components between rooms

Food & Beverage Production

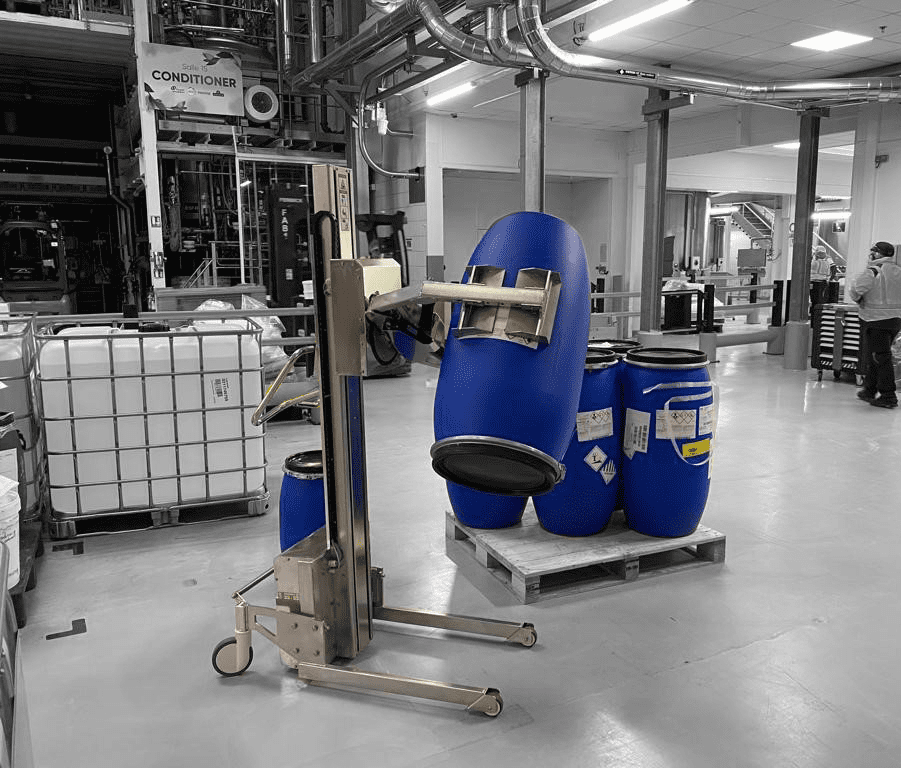

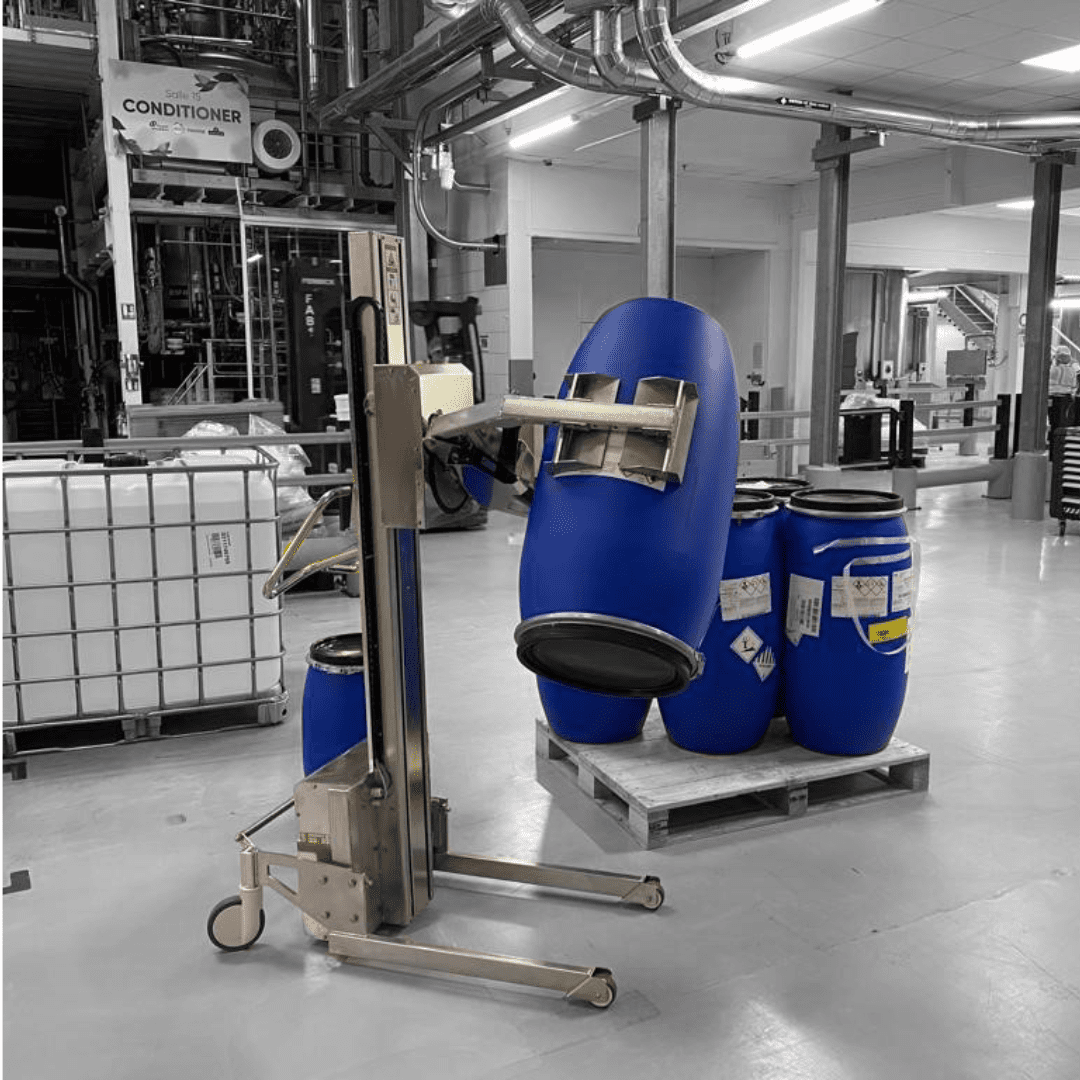

Reglift for Food Industry

Hygiene is critical in food-grade environments, and Reglift delivers. With IP-rated components, smooth surfaces, and no external lubrication, these lifters are ideal for HACCP-compliant operations. They withstand aggressive cleaning agents and pressure washing without degradation.

Key Features:

– Food-grade stainless steel construction

– Detergent- and chemical-resistant

– Non-porous, easy-clean design

– Custom attachments for trays, buckets, mixing vessels

Popular Use Cases:

– Lifting mixing containers in processing zones

– Transferring product trays or ingredients

– Supporting washdown-safe operations in open-plant areas

Logistics, Warehousing & Packaging

Reglift for Logistics & Light Industry

For high-throughput handling in non-cleanroom sectors, Reglift adds efficiency and safety to your floor operations. From carton lifting to tooling changes, these compact units are built to take the strain off your staff—and your process.

Key Features:

– Compact footprint, easy manoeuvrability

– Lifts up to 285 kg (depending on model)

– Configurable forks, clamps, and platforms

– Electric or manual operation

Popular Use Cases:

– Ergonomic lifting in production lines

– Height-adjustable pallet handling

– Warehouse kitting and order-picking support

Customisation Options

Need something specific? Reglift units are highly configurable. Choose from:

– Manual or electric operation

– Stainless forks, clamps, booms, platforms

– Narrow, wide, or low-profile bases

– Extended lifting heights for tall applications

– ATEX or cleanroom modifications (on request)

Why Choose Reglift?

✔ Audit-Ready Compliance: Every Reglift is CE-marked and can be supported by Hoistech’s SafeGuard digital inspection platform for full GA1 traceability.

✔ Local Support: Hoistech provides installation, servicing, and ongoing support across Ireland.

✔ Proven Experience: Trusted by leading pharma and food manufacturers across Europe.

Request a Quote or Site Consultation

Whether you’re designing a new cleanroom, upgrading old lifting equipment, or expanding your production line—Reglift can be configured to fit. Contact Hoistech today to discuss your needs.

Want to book a consultation? Get in touch now!